And Separation Solution Provider

Constantly meet customer needs and create value for customers

More Detail Inquiry NowRare Earth Elements(REE) contains 17 kinds of elements, they are lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm), europium (Eu), gadolinium (Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb), lutetium (Lu), yttrium (Y) and scandium (Sc).

Hydrometallurgy is a kind of chemical way to liquid-liquid separate and extract the Rare Earth. The whole process was involved in solution and solvent. The process can be precipitation, crystallization, oxidation-reduction, solvent extraction, and ion exchange etc.. Among them, the most commonly used method is organic solvent extraction, which is a universal process for industrial separation of high-purity single rare earth elements. The hydrometallurgy process is complex, and the purity of final products is high. The finished products produced by this method have a wide range of applications.

Why it is difficult to separate and extract single rare earth element by chemical process ?

It is very complicated and difficult to separate and extract the single rare earth element by chemical process. Mainly because of : 1. The physical and chemical properties between rare earth elements are very similar, making separation and purification extremely difficult. 2.There are many accompanying impurity elements , such as uranium(U), thorium(Th), niobium(Nb), tantalum(Ta), titanium(Ti), zirconium(Zr), iron(Fe), calcium(Ca), silicon(Si), fluorine(F), phosphorus(P), etc. Therefore, in the process of separating rare earth elements, it is necessary to consider not only the separation between rare earth elements with extremely similar chemical properties, but also the separation between impurity elements accompanying rare earth elements.

The separation methods for rare earth elements (wet production process) include:

(1)Step-by-step method (graded crystallization method, graded precipitation method, and redox method);

(2)Ion exchange method;

(3)Solvent extraction method.

Solvent extraction method utilize organic solvents(O) to extract and separate the solutes from an immiscible aqueous solution(A). This method is also known as organic solvent liquid-liquid extraction method, which is a mass transfer process that transfers substances from one liquid phase to another. It has advantages of good separation effect, large production capacity, convenience for rapid and continuous production, and easy implementation of automatic control compared with other separation methods.So it has gradually become the main method for separating large amounts of rare earths.

The main equipment for solvent extraction and separation has mixer settler, liquid-liquid extraction centrifuge. The extractants(solvent) used for purifying rare earths include cationic extractants represented by acidic phosphate esters such as P204 and P507, anion exchange liquid N1923 represented by amines, and solvent extractants represented by neutral phosphate esters such as TBP and P350. These extractants have high viscosity and specific gravity, making them difficult to separate from water. Usually dilute it with solvents such as kerosene and reuse it.

Tiei has specialized in laboratory mixer settlers, liquid-liquid extraction centrifuges(lab model,pilot model, industrial model) for many years. We can provide laboratory feasibility testing, preliminary design, pilot plant, industrial liquid-liquid extraction equipment manufacturing/commissioning and optimization.

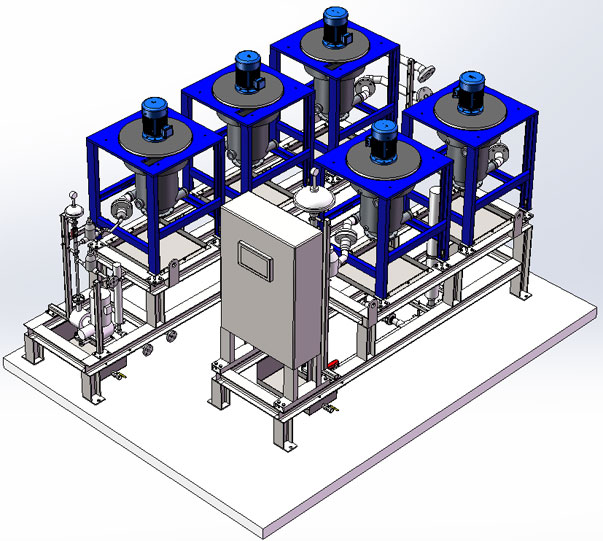

Solution 1:Liquid–Liquid Extraction Skid Platform

Liquid–Liquid extraction Centrifugal Extractor solutions are also available! You just need to tell our engineer your demand, and we will equip you the right Liquid–Liquid extraction Centrifugals with low energy consumption, low cost, and high efficiency.

TIEI Liquid–Liquid extraction Skid platform has exclusive benefits you cannot resist:

1. The Liquid–Liquid extraction equipment is small in size, the equilibration time is short, and the stock of the extractant tank is small.

2. The Liquid–Liquid extraction device has a large processing capacity and low power consumption.

3. High degree of automation and simple operation.

4. Liquid–Liquid extraction Skid platform can realize the closed operation of the extraction system, and the operating environment is good.

5. The Liquid–Liquid extraction Skid platform is compact in structure and occupies a small area.

6. Vertical direct motor drive, compact structure

7. Can be adapted to intermittent or continuous operation.

8. The internal volume of the Liquid–Liquid extraction Skid platform is small, saving extraction agent, solvent or detergent

9. The rotation speed and mixing method are easy to adjust, and can adapt to the requirements of different extraction systems.

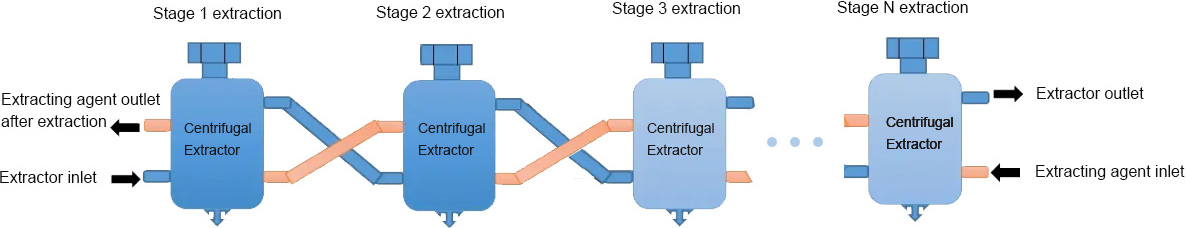

Solution 2:Multistage Liquid–Liquid Countercurrent Continuous Extraction

Multistage Liquid–Liquid Process Description:

1. The Multistage Liquid–Liquid Extraction process is not limited to four-stage pickling, alkali washing and water washing, and the number of countercurrent washing stages can be increased according to the actual situation;

2. The Multistage Liquid–Liquid Extraction process is suitable for separating organic mixtures immiscible with water such as acetochlor, alachlor, etc.;

3. The Multistage Liquid–Liquid Extraction process relies on centrifugal separation (hundreds to thousands of times the gravity under the same conditions), and the separation efficiency is high;

4. The Multistage Liquid–Liquid Extraction process equipment occupies a small area, low power consumption, and less residual liquid, which can realize the continuous production of the acetochlor washing

process section;

If you want to learn more about TIEI Liquid–Liquid Centrifugal Extractors, Leave Message Online

TIEI Liquid–Liquid centrifugal extractor is a new type of liquid-liquid extraction equipment developed by our company after many years of research, the Liquid–Liquid extraction equipment could realize mixed and mass transfer, reaction, extraction, washing and separation and many other functions. It has widely application in Pharmaceutica, Chemical, Food, Hydrometallurgy, Environmental and so on.

Mixing Flux:1000-150000 L/H

Model: CWL150-M; CWL250-M; CWL350-M;CWL450-M

Customized:YES

Focus on being Liquid–Liquid extraction Mixing And Separation Solution Provider.

We will reply you quicklyIf you want to learn more about our centrifugal extractor, mixer settler, Contact us Now

10-9, Enterprise Park,4th West Ring Road, Zhengzhou, China