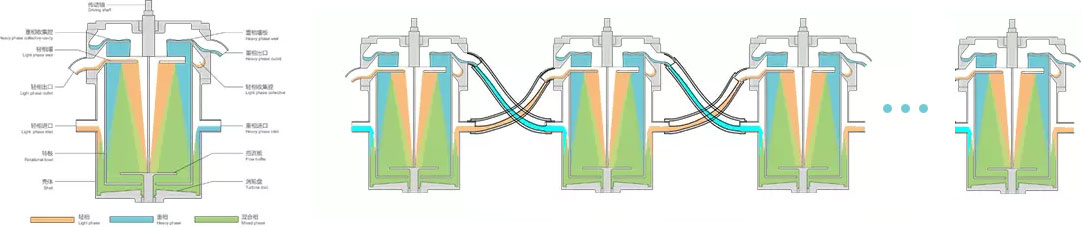

TIEI Liquid-liquid Centrifugal Extractor Work Principle

Upper hanging structure

Remove the bearing and

mechanical seal at the bottom

No leakage risk

Advanced multi cavity separation structure

achieve Good separation effect

under low rotation speed

Advanced multi cavity

separation structure

achieve Good separation effect

under low rotation speed

Mixing Structure (optional)

According to the material liquid

system Up to 6 line Mixing structure

Set special quick replacement heavyphaseweir plate

Avoid problem of destroying the dynamic balance of equipment

Modular production

Cover shell module, spindle module, drum module, bearing block module.....

1) Liquid-liquid Mixed mass transfer process

The two-phase solutions enter into the liquid-liquid mixing area of inside the shell from the two phase inlet ,which in a certain proportion to make the two phases mix

and disperse quickly and complete the liquid-liquid mixing mass transfer process.

2)Two phase Liquid-liquid separation process

The mixed liquid enters the drum under the action of the vortex disc or feeder. Under the action of centrifugal force, the heavy phase liquid gradually moves away

from the center of the drum and towards the drum wall in the upward flow process; The light phase liquid with low density gradually moves away from the drum

wall and towards the center. The clarified two-phase liquid finally enters the collection chamber through their respective weir plates and flows out from the light

phase outlet to complete the two-phase separation process.

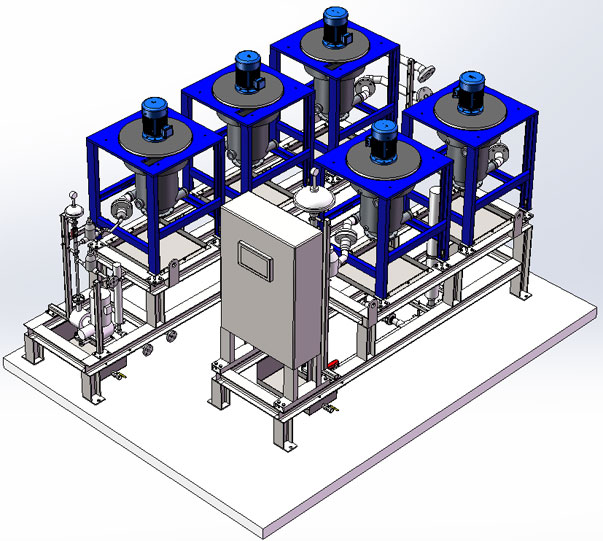

TIEI Extraction Skid-Mounted Systems

More than ten years of experience, TIEI Extraction designing and manufacture liquid-liquid extraction (LLE) / solvent extraction equipment. TIEI Extraction liquid-liquid Centrifugal Extractor are engineered to fulfill the challenging purification requirements that exist in the alternative energy, renewable chemicals, flavor, metals, petrochemical and hydrocarbons, pharmaceuticals, polymers, and specialty chemicals industries. TIEI Extraction do more than sell liquid-liquid extraction equipment; TIEI Extraction supply solutions to difficult liquid-liquid separation challenges. In order to meet the requirements of our clients, we developed the Skid system or platform.

Advantages of Skid-Mounted Systems

1. High degree of automation and simple operation.

2. It can realize the closed operation of the extraction system, and the operating environment is good.

3. The equipment is compact in structure and occupies a small area.

4. Skids are assembled as units, so skid mounted process equipment can be more easily disassembled and reassembled when required. This enables benefits such as: The relocation of skid-mounted equipment in an easy and secure manner.

Liquid-liquid Centrifugal Extractor Technical Specification

| Model | Diameter of Bowl (mm) | Applicable rotating speed | Max. Mixing Flux(L/H) | Pipe diameter of inlet and outlet(mm) | Two-phase flow ratio range | Motor Power(KW) | Unit Dimension |

| CWL150-M | 150 | 2270-2840 | ≤1000 | DN40 | 1/30~30/1 | 1.5 | 400×370×900 |

| CWL250-M | 250 | 1100-1350 | ≤3000 | DN50 | 1/30~30/1 | 1.5/2.2 | 750×750×1400 |

| CWL350-M | 350 | 1100-1350 | ≤8000 | DN80 | 1/30~30/1 | 3.0 | 950×950×1600 |

| CWL450-M | 450 | 654-817 | ≤15000 | DN100 | 1/30~30/1 | 4.0 | 1070×1070×1800 |

If you want to learn more about our Liquid–Liquid Centrifugal Extractors, Leave Message Online