And Separation Solution Provider

Constantly meet customer needs and create value for customers

More Detail Inquiry NowWith the rapid development of new energy industry in recent years, the price of Lithium has increased more than ten times,and the extraction of lithium from the mother liquor of precipitation lithium produced in the production process of Lithium has gradually been paid attention to.

After the lithium precipitation reaction is completed, the mother liquor of lithium precipitation contains a considerable part of lithium resources(1-2g/L). Treating it as sewage can have a huge impact on the environment, at the same time, it will cause more lithium loss in the production process. At present, solving the problem of mother liquor of lithium precipitation is a key point in the process of large-scale and continuous production of Lithium products.

Now the traditional technology to process mother liquor of lithium is : Hydrogen fluoride is added to the mother liquor to produce Lithium fluoride. The lithium extraction rate is only about 70%, and the mother liquor contains a large amount of fluoride ions, which has a great bad impact on the environment.

The mother liquor of lithium precipitation is directly returned to the system for recycling. Because the reaction of lithium precipitation is done by adding sodium carbonate. The mother liquor of lithium precipitation contains a considerable amount of sodium ions, chloride ions, and carbonate ions. Long term use of this method will inevitably lead to the enrichment of sodium ions, chloride ions, and carbonate ions throughout the entire process, especially the sodium ions do not have a system outlet. Eventually, the lithium precipitation reaction is carried out under the condition of where sodium chloride exists in large quantities, causing the sodium ion and chloride ion in the product to exceed the standard, which cannot meet the production needs.

The separation and concentration of lithium from other impurity components are achieved through organic solvent extraction of lithium, and the high concentration raffinate solution further produces various lithium salts. The advantage is that it can handle high magnesium lithium ratio brine and is easy to industrialize, but it has high requirements for extraction equipment(centrifuges). Extracting lithium through centrifuges is currently a relatively efficient lithium extraction technology.

High extraction and recovery rate

By using specialized lithium extraction extractant and centrifuge extraction processes, lithium can be directly extracted from the mother liquor of lithium precipitation. The lithium extraction yield can reach over 95%, and the lithium recovery rate is very high. High Li/Na separation coefficient and good selectivity.

Simple technical process

Less equipment, less land occupation, less extractant investment, fast construction, low investment, and easy promotion.

Low production cost

Using this extraction process to produce Lithium chloride solution from the mother liquor of lithium precipitation, the production cost is about 1000 USD, and the overall recovery rate of lithium can be increased by 15-20%.

Taking the production capacity of 10000t Lithium per year from mother liquor (produced from brine and ore process) as an example, about 25m3 of mother liquor is produced every hour, about 600m3 is produced every day, and 180000m3 is produced every year. The lithium in the mother liquor, equivalent to 1500t Lithium, is worth 60 million USD at the current market price of Lithium($40000/t).

At present, our centrifuges are successfully applied in the project of lithium extraction in qinghai. The project began the production in the early 2022. Now the feeding mother liquor of lithium precipitation is 15m3/h, and the current capacity of Lithium is 2-3tons per day.

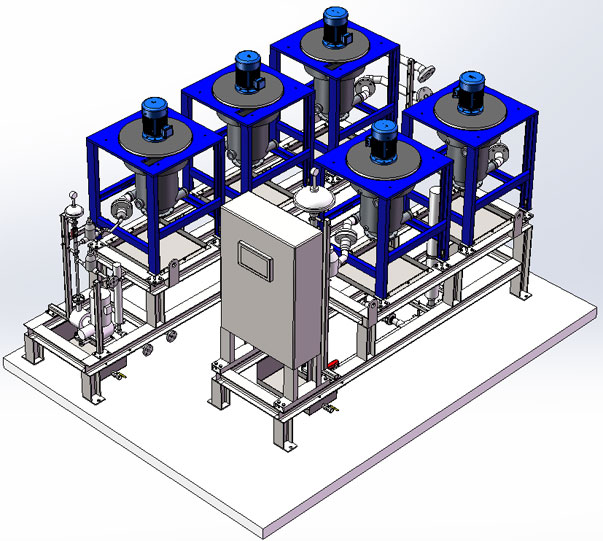

Solution 1:Liquid–Liquid Extraction Skid Platform

Liquid–Liquid extraction Centrifugal Extractor solutions are also available! You just need to tell our engineer your demand, and we will equip you the right Liquid–Liquid extraction Centrifugals with low energy consumption, low cost, and high efficiency.

TIEI Liquid–Liquid extraction Skid platform has exclusive benefits you cannot resist:

1. The Liquid–Liquid extraction equipment is small in size, the equilibration time is short, and the stock of the extractant tank is small.

2. The Liquid–Liquid extraction device has a large processing capacity and low power consumption.

3. High degree of automation and simple operation.

4. Liquid–Liquid extraction Skid platform can realize the closed operation of the extraction system, and the operating environment is good.

5. The Liquid–Liquid extraction Skid platform is compact in structure and occupies a small area.

6. Vertical direct motor drive, compact structure

7. Can be adapted to intermittent or continuous operation.

8. The internal volume of the Liquid–Liquid extraction Skid platform is small, saving extraction agent, solvent or detergent

9. The rotation speed and mixing method are easy to adjust, and can adapt to the requirements of different extraction systems.

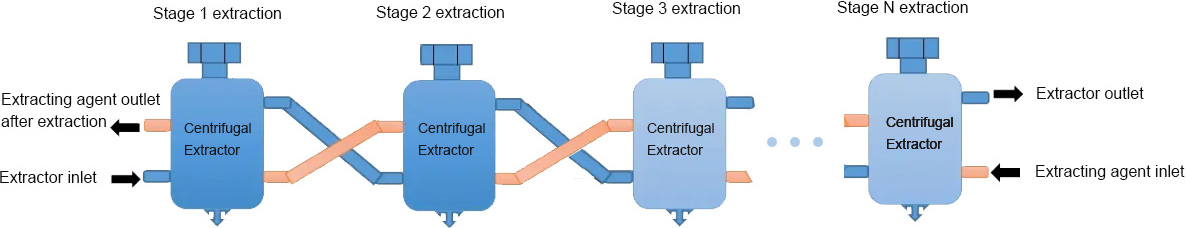

Solution 2:Multistage Liquid–Liquid Countercurrent Continuous Extraction

Multistage Liquid–Liquid Process Description:

1. The Multistage Liquid–Liquid Extraction process is not limited to four-stage pickling, alkali washing and water washing, and the number of countercurrent washing stages can be increased according to the actual situation;

2. The Multistage Liquid–Liquid Extraction process is suitable for separating organic mixtures immiscible with water such as acetochlor, alachlor, etc.;

3. The Multistage Liquid–Liquid Extraction process relies on centrifugal separation (hundreds to thousands of times the gravity under the same conditions), and the separation efficiency is high;

4. The Multistage Liquid–Liquid Extraction process equipment occupies a small area, low power consumption, and less residual liquid, which can realize the continuous production of the acetochlor washing

process section;

If you want to learn more about TIEI Liquid–Liquid Centrifugal Extractors, Leave Message Online

TIEI Liquid–Liquid centrifugal extractor is a new type of liquid-liquid extraction equipment developed by our company after many years of research, the Liquid–Liquid extraction equipment could realize mixed and mass transfer, reaction, extraction, washing and separation and many other functions. It has widely application in Pharmaceutica, Chemical, Food, Hydrometallurgy, Environmental and so on.

Mixing Flux:1000-150000 L/H

Model: CWL150-M; CWL250-M; CWL350-M;CWL450-M

Customized:YES

Focus on being Liquid–Liquid extraction Mixing And Separation Solution Provider.

We will reply you quicklyIf you want to learn more about our centrifugal extractor, mixer settler, Contact us Now

10-9, Enterprise Park,4th West Ring Road, Zhengzhou, China