And Separation Solution Provider

Constantly meet customer needs and create value for customers

More Detail Inquiry NowLactic acid and citric acid are widely application in the food,pharmaceutical, especial the demand for Lactic acid has increased considerably because of its use as a monomer in the preparation of PLA,which is a biodegradable and biocompatible polymer that will replace polyethylene and PE plastic, eliminate the pollution of "white plastic" to nature and deal with the problems caused by the reduction of resources such as oil.

Produce organic acids has many methods, but the most promising is biological fermentation.Produced by fermentation, organic acids are generally low in concentration and accompanied by impurities, and the coupling separation process to extract organic acids is an effective means of extraction, separation and concentration.

1. High output Yield

Highly efficient of coupling adsorption system

2. Better Quality

High-quality Grade with good thermal stability

3. Less waste water, No waste residue

Less pollution, application in industrialized clean production

4. Low Production Cost

Process of Coupled adsorption separation under normal pressure

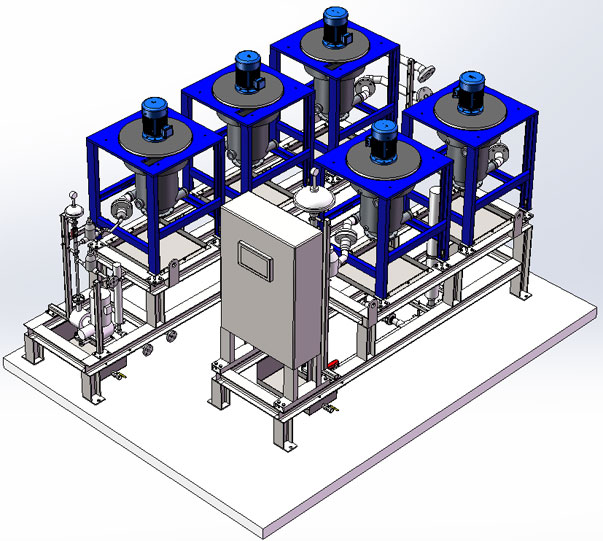

Solution 1:Liquid–Liquid Extraction Skid Platform

Liquid–Liquid extraction Centrifugal Extractor solutions are also available! You just need to tell our engineer your demand, and we will equip you the right Liquid–Liquid extraction Centrifugals with low energy consumption, low cost, and high efficiency.

TIEI Liquid–Liquid extraction Skid platform has exclusive benefits you cannot resist:

1. The Liquid–Liquid extraction equipment is small in size, the equilibration time is short, and the stock of the extractant tank is small.

2. The Liquid–Liquid extraction device has a large processing capacity and low power consumption.

3. High degree of automation and simple operation.

4. Liquid–Liquid extraction Skid platform can realize the closed operation of the extraction system, and the operating environment is good.

5. The Liquid–Liquid extraction Skid platform is compact in structure and occupies a small area.

6. Vertical direct motor drive, compact structure

7. Can be adapted to intermittent or continuous operation.

8. The internal volume of the Liquid–Liquid extraction Skid platform is small, saving extraction agent, solvent or detergent

9. The rotation speed and mixing method are easy to adjust, and can adapt to the requirements of different extraction systems.

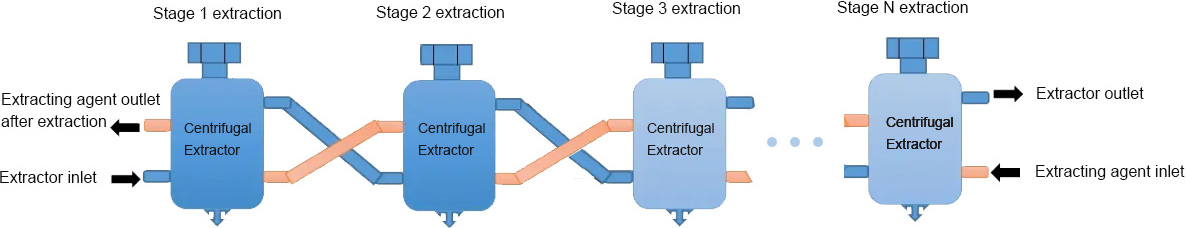

Solution 2:Multistage Liquid–Liquid Countercurrent Continuous Extraction

Multistage Liquid–Liquid Process Description:

1. The Multistage Liquid–Liquid Extraction process is not limited to four-stage pickling, alkali washing and water washing, and the number of countercurrent washing stages can be increased according to the actual situation;

2. The Multistage Liquid–Liquid Extraction process is suitable for separating organic mixtures immiscible with water such as acetochlor, alachlor, etc.;

3. The Multistage Liquid–Liquid Extraction process relies on centrifugal separation (hundreds to thousands of times the gravity under the same conditions), and the separation efficiency is high;

4. The Multistage Liquid–Liquid Extraction process equipment occupies a small area, low power consumption, and less residual liquid, which can realize the continuous production of the acetochlor washing

process section;

If you want to learn more about TIEI Liquid–Liquid Centrifugal Extractors, Leave Message Online

TIEI Liquid–Liquid centrifugal extractor is a new type of liquid-liquid extraction equipment developed by our company after many years of research, the Liquid–Liquid extraction equipment could realize mixed and mass transfer, reaction, extraction, washing and separation and many other functions. It has widely application in Pharmaceutica, Chemical, Food, Hydrometallurgy, Environmental and so on.

Mixing Flux:1000-150000 L/H

Model: CWL150-M; CWL250-M; CWL350-M;CWL450-M

Customized:YES

Focus on being Liquid–Liquid extraction Mixing And Separation Solution Provider.

We will reply you quicklyIf you want to learn more about our centrifugal extractor, mixer settler, Contact us Now

10-9, Enterprise Park,4th West Ring Road, Zhengzhou, China