And Separation Solution Provider

In chemical production, deacidification, purification and reuse of solutions that are immiscible with water such as benzene and xylene is an important process. Currently, traditional reactors are still used for manual operation, resulting in low production efficiency and high labor intensity. , can no longer meet the needs of modern chemical production. The CWL-M new centrifugal extraction equipment developed by Zhengzhou TIEI Extraction Company has become the "new favorite" in the field of chemical liquid-liquid extraction and separation, and has achieved excellent application results.

The purpose of this process is to remove organic acids and inorganic acids from benzene-containing solutions and purify benzene for reuse. In this process, the required reagents include sodium hydroxide, potassium hydroxide, ammonia and water. The entire process is divided into two steps: alkali elution acid elution and water elution desalination.

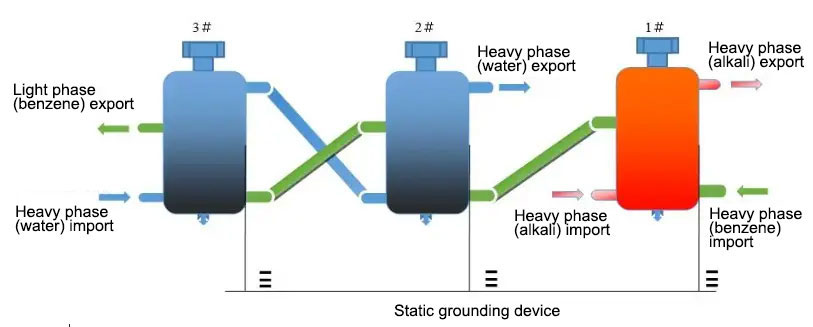

In the alkali elution acid phase, after the CWL-M Liquid Liquid Centrifugal Extractor is turned on, water and sodium hydroxide are injected into the heavy phase port of the CWL-M centrifugal extractor and the heavy phase port of the 1# centrifugal extractor through the metering pump. The acid-containing benzene solution is pumped from the light phase port into the 1#CWL-M centrifugal extractor for countercurrent extraction. In the mixing zone, sodium hydroxide neutralizes the acid in the benzene solution, and then the mixed phase enters the high-speed separation zone for rapid separation.

In the water washing and desalting stage, 2# and 3# CWL-M Liquid Liquid Centrifugal Extractors are used for two-stage countercurrent water washing and desalting. The benzene solution after acid elution with alkali enters the 2#CWL-M centrifugal extractor and completes the desalting process in the high-speed separation zone. The entire process also includes measures to eliminate static electricity inside the equipment. Zirconium wire is placed inside the equipment to dissipate static electricity and eliminate safety hazards.

This process has the following characteristics: it is not limited to three-stage centrifugal separation, and the number of countercurrent extraction stages can be increased according to actual conditions; it is suitable for separation and recovery of acid-containing organic mixtures that are immiscible with water; the total volume of residual liquid in the cavity after the equipment stops running less; continuous production can be achieved; all equipment is equipped with electrostatic discharge devices, and the material is zirconium.

The CWL-M centrifugal extractor of Zhengzhou TIEI Extraction plays a key role in this process. Its advantages include small footprint, high stage efficiency, low power consumption, fully enclosed design, flexible operation, etc. The host material is selected as composite Material, good corrosion resistance. Less residual liquid in the equipment can greatly reduce the consumption of alkali solution and water and reduce production costs. When the customer's processing capacity requirement is 8m³/h, TIEI Extraction generally selects a CWL350-M centrifugal extractor for the customer.

By using Zhengzhou TIEI Extraction's CWL-M centrifugal extractor, chemical companies can achieve continuous production of deacidification and purification of benzene solutions, and significantly reduce raw material costs. This advanced technology will bring more sustainable and environmentally friendly production methods to the chemical industry and promote the development and progress of the industry.

Zhengzhou TIEI Extraction will continue to be committed to R&D innovation and technological improvement, provide customers with better centrifugal extraction solutions, and make greater contributions to the development of the chemical industry.

If you have any other questions or needs, please feel free to contact us at any time. Thank you for your support and cooperation!

Focus on being Liquid–Liquid extraction Mixing And Separation Solution Provider.

We will reply you quicklyIf you want to learn more about our centrifugal extractor, mixer settler, Contact us Now

10-9, Enterprise Park,4th West Ring Road, Zhengzhou, China